Double belt presses

Double belt presses

In order to avoid possible irregularities and to ensure homogeneity in the composite material, the material is gently heated by divided heating zones, compressed or brought to the desired level and glued together. The cooling system, which is also divided into zones, ensures optimum cooling of the product. The individual heating and cooling processes in the zone areas play a decisive role here.

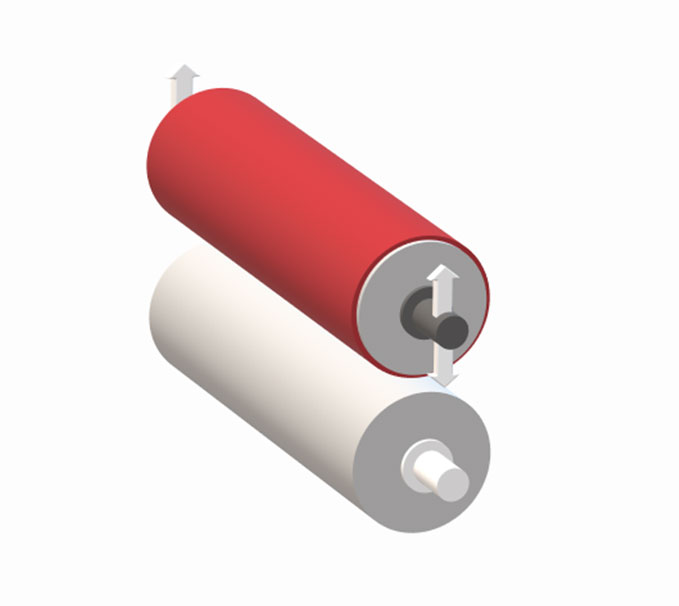

A height-adjustable press roller for high pressure requirements on the material is also available. This pair of press rollers is placed between the heating and cooling system and can optionally also be temperature-controlled or cooled.

A height-adjustable press roller for high pressure requirements on the material is also available. This pair of press rollers is placed between the heating and cooling system and can optionally also be temperature-controlled or cooled.

The double belt presses from LiTW GmbH work continuously and are used to laminate or glue different materials together. All types of materials in rolls or sheets can be glued, coated or compressed with the help of thermoplastic adhesives under the influence of certain process parameters such as surface pressure, press roller pressure, heating temperature, cooling temperature, speed and inlet and outlet gap. It is important to determine these parameters beforehand on the basis of tests in our test laboratory. Our test laboratory is equipped accordingly for our customers and can be booked and used at any time for a small daily flat rate. Various types of adhesive media are available here. Depending on the application and process, we can give our recommendations when selecting an optimal system solution according to your wishes.

| Heating length (mm) | Cooling length (mm) | max. Working width (mm) | Height adjustment (mm) | |

|---|---|---|---|---|

| DBP-XS | 480 | 370 | 400 / 600 | 150 |

| DBP-S | 760 | 560 | 600 / 1.000 | 150 |

| DBP-M | 1.375 | 1.175 | 1.100/ 1.300/ 1.500/ 1.700/ 1.900/ 2.100/ 2.300/ 2.500 | 150 |

| DBP-Li | 1.570 (interval) | 970 (interval) | 1.100/ 1.300/ 1.500/ 1.700/ 1.900/ 2.100/ 2.300/ 2.500 | 150 |

| DBP-XLa | 2320 | 1175 | 1.100/ 1.300/ 1.500/ 1.700/ 1.900/ 2.100/ 2.300/ 2.500/ 2.700 | 150 |

| DBP-XLb | 2320 | 2320 | 1.100/ 1.300/ 1.500/ 1.700/ 1.900/ 2.100/ 2.300/ 2.500/ 2.700 | 150 |

| DBP-XXL | 3.050 (modulary 1.500 expandable) | 1.550 (modulary 1.500 expandable) | 1.100/ 1.300/ 1.500/ 1.700/ 1.900/ 2.100/ 2.300/ 2.500/ 2.700/ 2.900/ 3.100/ 3.400 | 150 |

Types of double belt presses

Depending on customer requirements, different variants of double belt presses are available, which are designed and equipped differently in terms of design. The length of the heating and cooling zones as well as the zone division play a decisive role here. Due to the modular design, the heating and / or cooling zones can be changed at any time, depending on the desired product.

Properties of the LiTW double belt presses

- flexibly arranged heating elements

- Edge zone division in the entire heating system

- Different materials and material thicknesses possible

- Multi-layer composite materials possible

- For sheet and sheet material

- Temperature from 20 ° C - 250 ° C individually adjustable in all zones

- Heating system optionally heated electrically or thermal oil

- Modular quick change systems

- For bonding, heat setting, calibration and / or surface consolidation

- For working widths between 300 - 3000 mm