Push-bend systems for pipes and pipe sockets

Push-bend systems for pipes and pipe sockets

The push-bending system is a semi-automatic system for the non-cutting shaping of pipes and pipe sockets. The system is loaded manually, while the workpiece removal is preferably automated.

The device can be equipped with tools that are individually designed for a certain type of component and can be exchanged accordingly as a complete unit.

The device can be equipped with tools that are individually designed for a certain type of component and can be exchanged accordingly as a complete unit.

Push-bend system

Pipe before

Pipe after

Bending process:

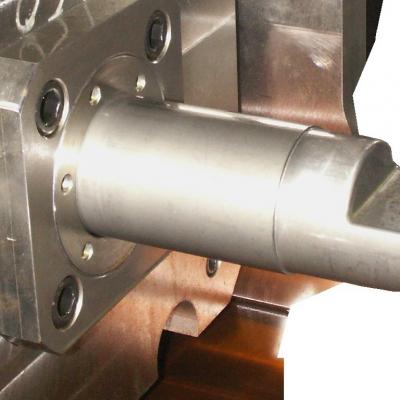

The workpiece is placed on the sliding mandrel by hand. After pressing the pushbutton, the receiving mandrel on the opposite side swivels back into the receiving position, the left and right mold halves being moved together via their locking cylinders.

For the forming process, the sliding mandrel with the attached pipe socket moves into the tool, with a short pause in the end position. The workpiece is then released. The sliding mandrel and mold halves move back to their starting positions. The finished workpiece is swiveled into the pick-up position for the loading portal via the fixing mandrel. From this it can be taken over and placed on a conveyor belt.

For the forming process, the sliding mandrel with the attached pipe socket moves into the tool, with a short pause in the end position. The workpiece is then released. The sliding mandrel and mold halves move back to their starting positions. The finished workpiece is swiveled into the pick-up position for the loading portal via the fixing mandrel. From this it can be taken over and placed on a conveyor belt.

Properties

- High repeat accuracy, as an individual tool is available for each component type

- Short changeover times by exchanging the tool in the modular system

- Long service life, low tool wear

- Easy replacement of the wearing parts (sliding and fixing mandrel)

- Very short cycle times

- Good interlinking option at the machine outlet

Push-bending system

Push-bending system with a robot cell